Glass laminating autoclave is widely used for the production of diverse laminated safety glass from small car windshields to large architectural laminated glass.

Autoclave lamination process.

The cycle completes after 30 60 minutes.

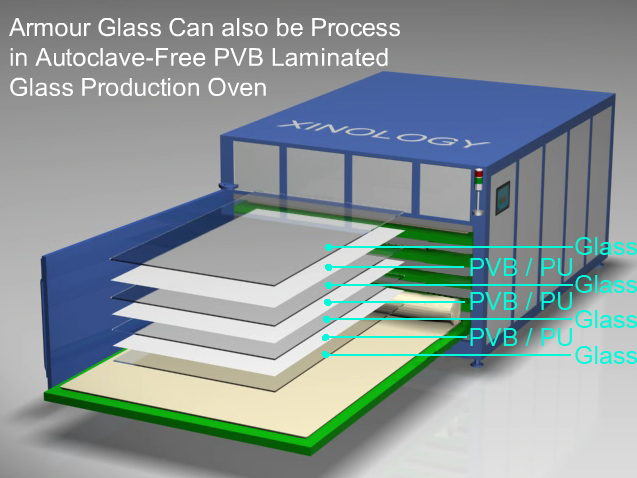

The process is also used for laminating temperature and pressure sensitive products as well as those with decorative and functional inserts.

In the manufacturing process the assembly of float glass and pvb are laminated together and then placed in an autoclave.

Enjoy the videos and music you love upload original content and share it all with friends family and the world on youtube.

Every single autoclave made by scholz for the production of laminated safety glass is a custom product.

Hence we take the greatest effort to fulfil all our customers requirements right down to the slightest detail.

Glass laminating autoclaves operate in a similar manner but serve another purpose.

We had been providing standard or custom glass laminating machines to meet your specific glass laminating process with automatic controlled pressure and temperature.

The main principle of the developed non autoclave glass laminating technology is the exclusive heating of an adhesive film in a low pressure environment via shortwave infrared radiation.

A typical autoclave lamination cycle ramps pressure to 180 psi 12 4 bar and temperature to 280 f 137 c.

Bondtech s line of glass laminating autoclaves can perform in accordance with virtually any manufacturer s requirements.